Advantages of EC Motor and EC Centrifugal Fan

1. Can save 1/3 energy than AC equivalent, Save your money.

2. Low motor temperature: for longer lifetime than AC equivalent;

3. 100% speed controllable, not frequency dependence.

4. Can be set-up for constant airflow or constant pressure applications, 0-10VDC or PWM control signal;

5. Electronic & power transformations are completely integrated within the motor.;

6. Speed can be driven up to 3600rpm, one EC fan replace multiple type of motors (2, 4 and 6 pole);

7. Easy connection : No complicated wiring and set-up with a frequency controller.

High airflow Garment Cabinet EC backward Centrifugal Fan 230V for clean room technical detail

| Rated voltage | 230 | VAC |

| Frequency | 50/60 | Hz |

| Rated voltage range | 207~253 | VAC |

| Power input | 505 | W |

| Speed | 1970 | RPM |

| Airflow | 3750 | M3/H |

| Current draw | 3.21 | A |

| Noise | 77 | dBA |

| Min.ambient temperature | -25 | oC |

| Max.ambient temperature | 60 | oC |

| Net weight | 5.7 | kg |

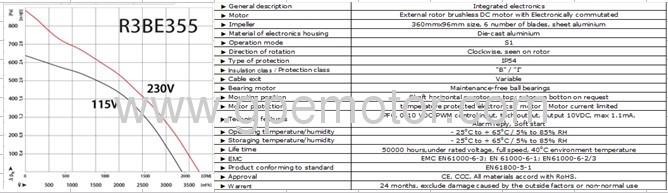

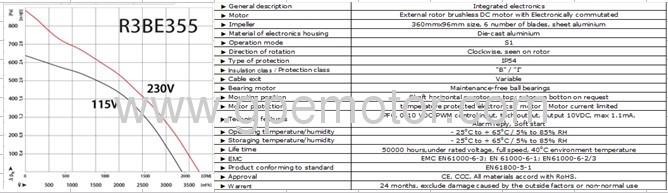

High airflow Garment Cabinet EC backward Centrifugal Fan 230V for clean room curve chart

Application:

Clean room equipment :GARMENT Cabinets with EC backward curved Centrifugal Fans are specially designed to prevent deposit of dust and other particles on clean room garments when not in use. An integral HEPA filter and blower assembly provides a continuous wash of class 100 air over the garments.

Pharmaceuticals and chemical research laboratories.

University clinics.

Electronic industry.

Optical industry.

Semiconductor production.

System engineering.

Aerospace

Nuclear industry.

Food processing industry.