ECMs are

DC motors that function using a built-in inverter and a magnet rotor, and as a result are able to achieve greater efficiency in air-flow systems than some kinds of AC motors. (Although AC current is used for ECM, the ECM's internal rectifier converts the current to DC voltage). Permanent split capacitor (PSC) motors, often used in conjunction with electronic SCR motors, are somewhat inefficient when used in air control systems because the

fan motor noise requires the motor to run at less than a full load. When turned down, PSC efficiency suffers and falls in the range of 12 to 45 percent. ECMs, on the other hand, maintain a high level (65 to 75 percent) of efficiency at a variety of speeds. As a result, ECMs are cost and energy efficient and can reduce operating costs. Additionally, ECMs are not prone to overheating and do not require additional measures to offset the generation of heat, as PSCs often do.

.

ECMs are also relatively low-maintenance; the use of true ball bearings reduces the need for oiling, and varied start-up speeds reduce stress on mounting hardware. The operating range is significant enough to enable one ECM to replace two

induction-style models, which simplifies the replacement, maintenance, and installation processes, and minimizes product choices. However, not all ECM motors run at variable speeds and selection depends heavily upon application specifications. The initial cost of an ECM can be high, but is typically balanced by overall energy savings in the long run.

The specifications:

| Model | Rated Voltage (VAC) | Frequency (Hz) | Rated Speed (RPM)) | Speed control |

| 113-1/3hp | 220 | 50 / 60 | 1300 | 0-10V/PWM |

The features:

1. 120V or AC240 (180-270V), 50/60Hz

2. EC

Motor: Die cast aluminum housing and cover, stainless steel shaft

3. Variable Speed Control: 0-10VDC/PWM signal

4. Separate driver or integrated driver

5. The insulation Class is "B"

6. Bearings: Maintenance-free ball bearings

7. Optional:thermostat, different voltage, bracket sizes, shaft sizes, single shaft and double shaft.

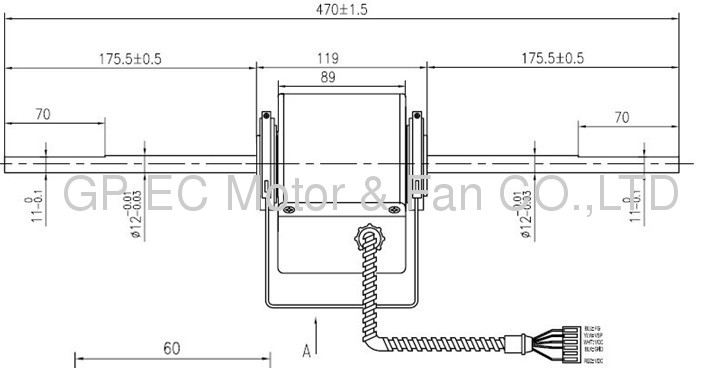

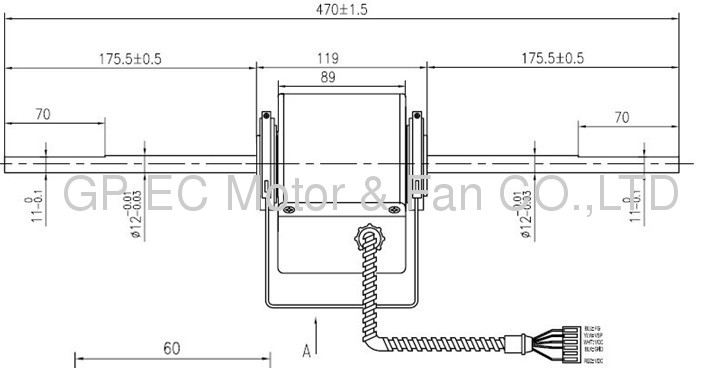

The outlines:

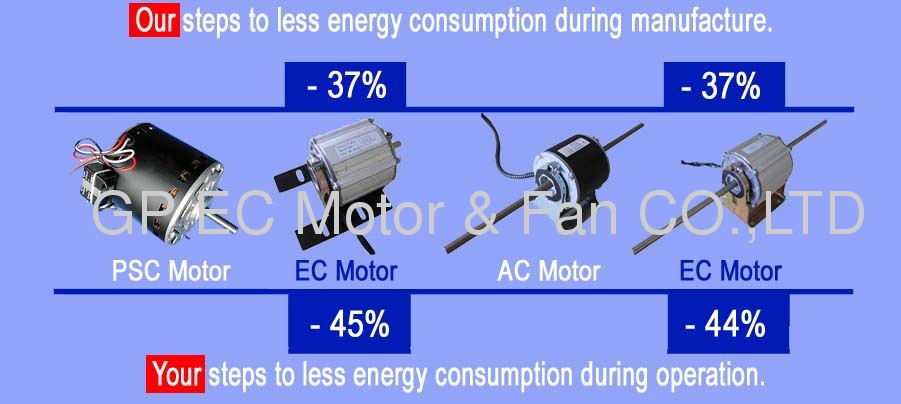

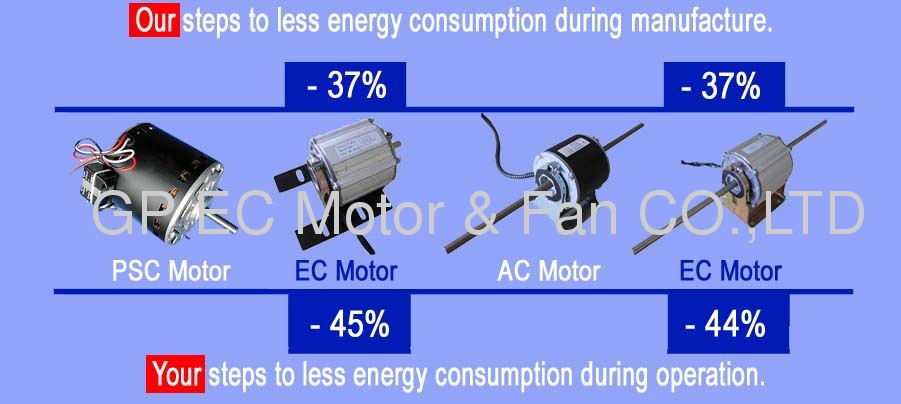

Energy saving of ECM Motors