The various advantages of ECM motor

The various advantages of the EC motor resulting from the use of state-of-the-art electronics make it the recommended choice for both air and drive engineering:

1)High Efficiency resulting in energy saving and fast amortization

2)Continuously variable speed control by analog or digital input 0-10V/PWM

3)Simple speed control or more complex closed-loop control options can be integrated at competitive cost

4)Cross linked bad bus-connected installations are easy to achieve

5)High performance density, i.e. compact design

6)Temperature, CO2, humidity and airflow-dependent speed control options (intelligent fans)

7)Minimal heat load due to extremely high efficiency.

8)Speed and/or air flow monitoring

9)Longer life resulting from lower rise temperatures, maintenance-free ball bearing and soft-start.

11)Built-in protective systems ( e.g. Looked rotor protection, reverse polarity protection)

12)Easy connection : No complicated wiring and set-up with a frequency controller..

13)Can be operated directly from AC mains supply, or from DC.

The features of 1/5hp ECM motor

1. 120V or AC240 (180-270V), 50/60Hz

2. EC Motor: Die cast aluminum housing and cover, stainless steel shaft

3. Variable Speed Control: 0-10VDC/PWM signal

4. Separate driver or integrated driver

5. The insulation Class is "B"

6. Bearings: Maintenance-free ball bearings

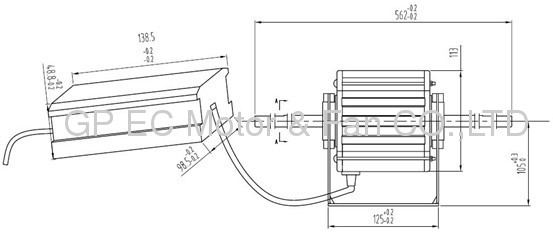

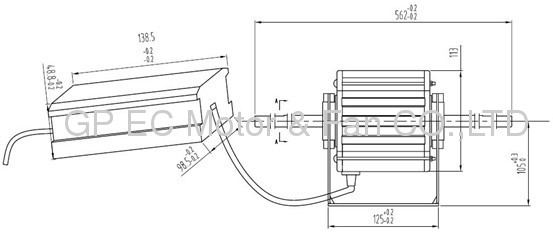

The outlines:

The data sheet of 1/5hp ECM motor

The data sheet of 1/5hp ECM motor

| Model | Rated Voltage (VAC) | Frequency (Hz) | Rated Speed (RPM)) | Speed control |

| ECI-113D/S-150 | 220 | 50 / 60 | 1400 | 0-10V/PWM |

| Rated Power (Watt) | Rated Current (A) | Ambient Temp. (oC) | Ambient RH % | N.W (kg) |

| 150W | 0.90 | -20 ~ +40 | 5% - 85% | 5.0 |