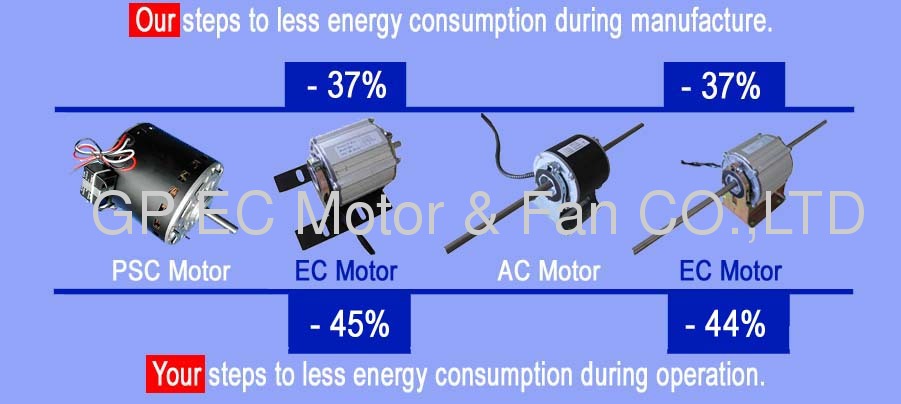

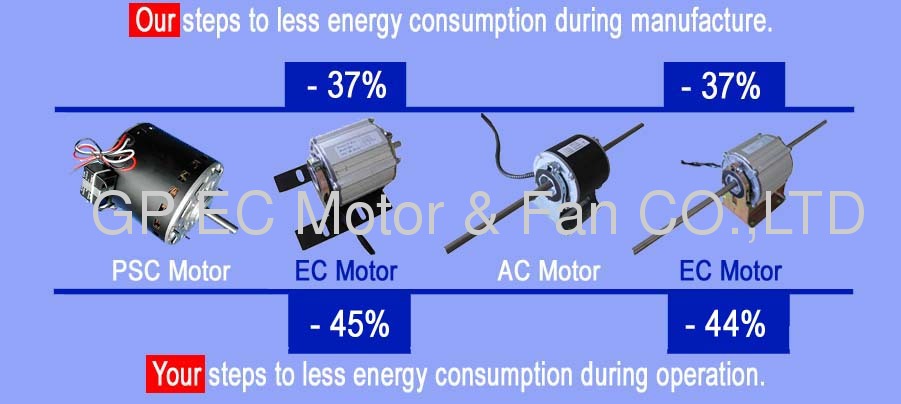

When considering an ECM for application in an HVAC system, there are several factors to keep in mind. Although ECMs are often selected because many models run at variable speeds, in certain condenser applications it is preferable to select and ECM that runs at a fixed speed—an ECM running at a fixed speed s in a condenser unit still uses less energy than a typical PSC motor running at a fixed speed in a similar unit. As a result of increased energy savings, a condenser operating with an ECM will have a higher SEER (seasonal energy efficiency ratio) rating. In other HVAC units, an ECM can run at variable speeds but depends on a controller that pre-programs speed, including the rate at which the motor ramps up. Whereas typical PSC

motors start and almost immediately run at full capacity, an ECM can start slowly and stop slowly, which can help reduce humidity. Additionally, the control can be set to alter the amount of air an ECM motor drives through the system, which enables a greater range of possible air-flow rates.

A typical ECM operating in an HVAC system will go through several stages, as determined beforehand by a manufacturer or a preprogrammed controller. In its first stage, and ECM runs at a lower speed to remove humidity (this is especially important in a cooling system). Next, the ECM reaches its designated peak speed, as specified for the application, maintaining high efficiency despite any shifts in operating speed. When the ECM stops, it can be programmed to stop slowly (called asoft stop).

The specifications:

| Model | Rated Voltage (VAC) | Frequency (Hz) | Rated Speed (RPM)) | Speed control |

| ECI-113D/S-120 | 220 | 50 / 60 | 1400 | 0-10V/PWM |

| Rated Power (Watt) | Rated Current (A) | Ambient Temp. (oC) | Ambient RH % | N.W (kg) |

| 120W | 0.70 | -20 ~ +40 | 5% - 85% | 4.8 |

The features:

1. 120V or AC240 (180-270V), 50/60Hz

2. ECM Motor: Die cast aluminum housing and cover, stainless steel shaft

3. Variable Speed Control: 0-10VDC/PWM signal

4. Separate driver or integrated driver

5. The insulation Class is "B"

6. Bearings: Maintenance-free ball bearings

7. Type of protection: exceed voltage limit, overcurrent protection, locked protection,etc

8. Optional:thermostat, different voltage, bracket sizes, shaft sizes, single shaft and double shaft.

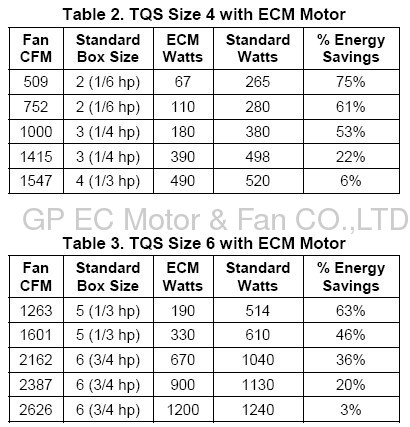

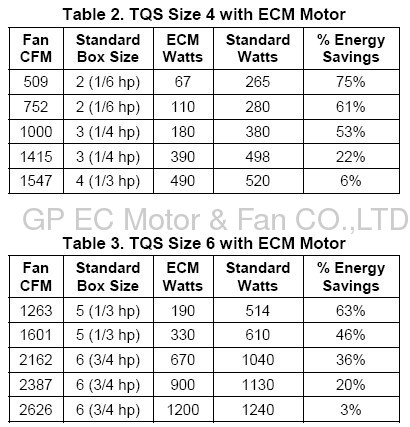

ECM motor vs PSC motor comparistion: